Reticulated Porcelain

One of the most elegant and prized porcelain objects from times gone by was Reticulation. It has, then and now, been an extremely time consuming Artform to produce. An artisan must hand cut out each and every hole from each and every cast! This methodology takes a great deal of time! I have reinvented the wheel by making it possible to produce entire casts in seconds with our FASTCAST SYSTEM.

George F. Engel

19th Century Reticulated Vases by Royal Worcester

Our FASTCAST SYSTEM is ideal to produce thicker reticulated casts in just seconds. For wafer-thin casts simply brushing-in and troweling-in thickened porcelain slip into the rubber mold would work best. The two methods I described would be used for simple, open-faced molds made for objects such as Christmas ornaments and for more complex objects, such as soup bowls, dinner plates, etc., (having two finished sides). Either way, the castings produced will be far more beautiful and can be far more complex with great delicacy.

Below you will see a row of amazingly complex and delicate reticulated castings we produced. Below them are Lenox’s casts formed utilizing ‘pressure casting’. The same level of quality of the magnificent works created in the 19th century (as seen above), can now be bettered utilizing my breakthrough technologies as exemplified by our reticulated castings immediately below.

George F. Engel

The upper three images (our DIAMOND GRILL, ROSETTE and CLOUD DISC Christmas ornaments) give an accurate depiction of what my technology and methodology can achieve when applied to Reticulated Porcelain. Some of the ‘wire-work’ of the ROSETTE is literally the width of very thin cardboard. All three of the porcelain pieces were made in an ‘open-faced’ rubber mold. The lower five Lenox Christmas ornaments displayed showing castings that are indicative of lackluster objects mass-produced by ‘pressure casting’.

This image is from Herend Porcelain’s own website. It shows a worker in the midst of cutting holes one at a time in each and every cast they make. This is a very laborious method requiring much hand-time.

Our FASTCAST SYSTEM allows us to inject slip into our rubber molds and thereby reproduce this same item in seconds ~ achieving castings of superior quality and at a fraction of the time/labor cost.

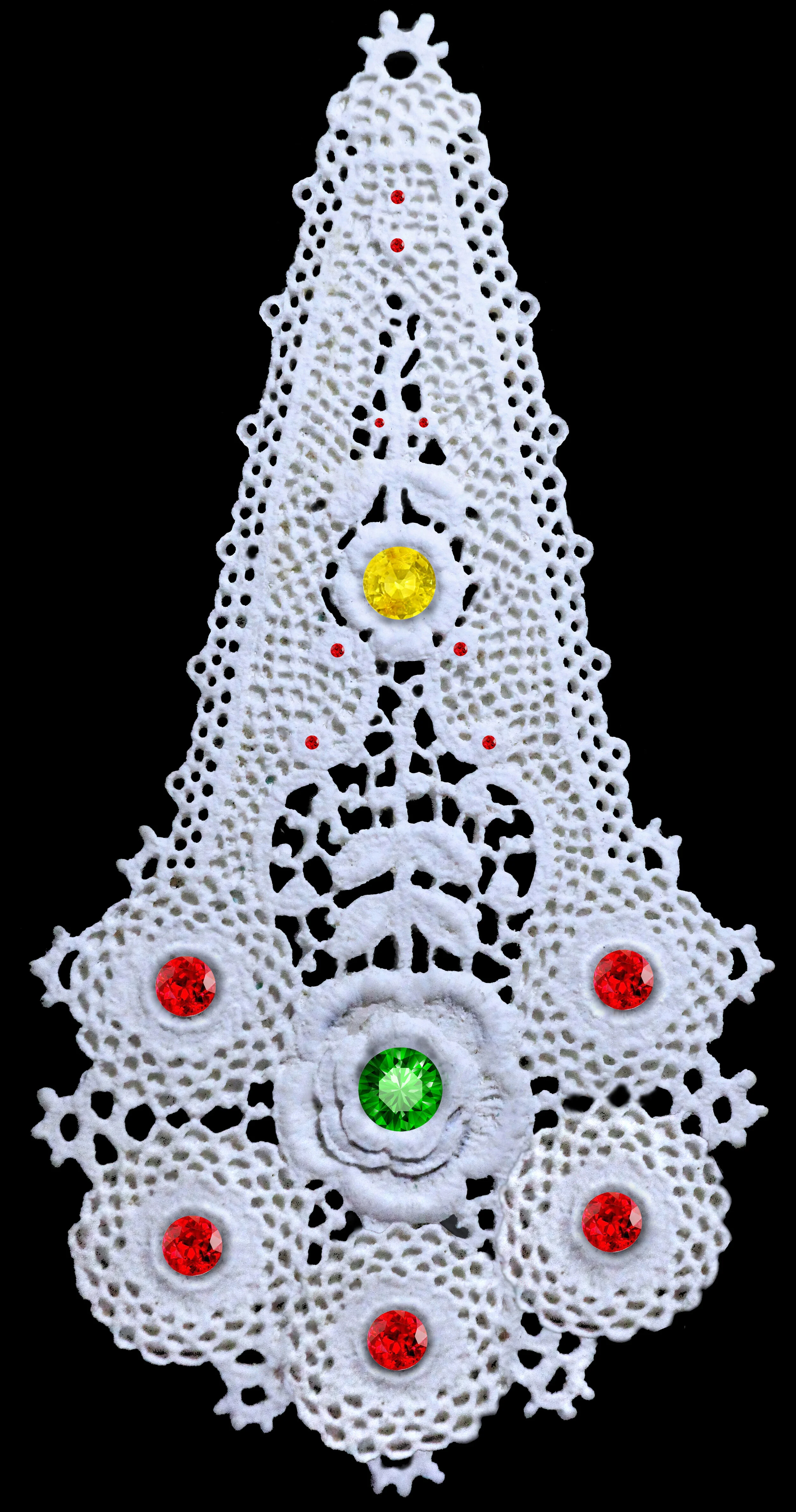

CHRISTMAS ORNAMENT Reticulated Porcelain With Swarovski Jewels (4" Tall)

CHRISTMAS ORNAMENT Reticulated Hand-Tinted Porcelain (7" Tall)

CHRISTMAS ORNAMENT Wafer-Thin Reticulated Porcelain Lace With Swarovski Jewels (6" Tall)

![CHINESE VILLAGE 6" Ivory Carving [L]

Greenware Jasperware Porcelain Cast [C & R]

Formed In Mere Seconds As Part Of My {Then As Yet Untested 'Proof Of Concept'}

FASTCAST SYSTEM Proving To Be A Self-Evident And Completely Successful Test](https://images.squarespace-cdn.com/content/v1/610a062b73399f60760b4c2c/7e59e5b4-60e9-44fc-b419-441b6c4fc626/Chinese+Village+MONTAGE+HERO.jpg)

CHINESE VILLAGE 6" Ivory Carving [L] Greenware Jasperware Porcelain Cast [C & R] Formed In Mere Seconds As Part Of My {Then As Yet Untested 'Proof Of Concept'} FASTCAST SYSTEM Proving To Be A Self-Evident And Completely Successful Test

![RETICULATED NAPKIN RING

[Test] Casts In Both Reticulated And Jasperware Porcelain

(3" Diameter)](https://images.squarespace-cdn.com/content/v1/610a062b73399f60760b4c2c/1f8d3d48-1b0d-479b-9544-ef78df0ad333/Napkin+Ring++Bamboo.jpg)

RETICULATED NAPKIN RING [Test] Casts In Both Reticulated And Jasperware Porcelain (3" Diameter)

RETICULATED DINNER PLATE Cast In A Two-Piece Rubber Mold (12" Diameter)

RETICULATED IVORY 'PAINT POT' Our Jasperware Test Cast Version Of This Same Design Can Be Seen On Our JASPERWARE PORCELAIN Page Reticulated Porcelain Test (4" Tall)